BATTERY MARKING MACHINE

BATTERY MARKING MACHINE

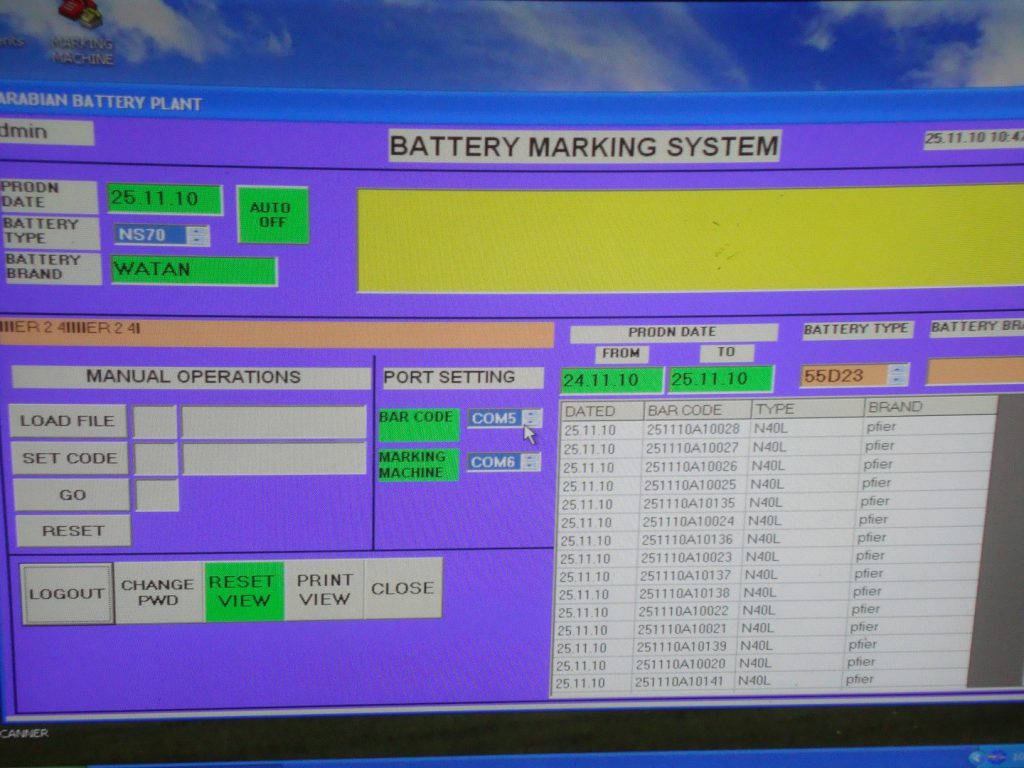

C-Link has proven expertise in manufacturing of battery marking automation systems. Till date C-Link has successfully provided marking automation solutions for variety of material. The marking methods employed are dot pin marking, laser marking and scribing. C-Link provides both stand alone marking machines as well as can integrate the marking systems with existing setup in plants. The video link shows a video of battery marking automation where the bar code sticker pasted at earlier stage on battery container is scanned using an image scanner and the same is then marked on the plastic battery container using dot pin marking.

Features of Battery Marking Automation

( As can be seen in video ) :

- Trolley mounted conveyor design to for at site maneuvering to align with existing conveyor line.

- PC based control logic for soft panel design, data storage, processing and reporting.

- Use of industrial grade steel for sturdy and reliable mechanical structure.

- Flexibility in design to cater to different sizes of battery.

- User friendly error reporting software for quick trouble shooting.

- Use of branded components for higher reliability and maintenance free operation.

- Customization as per customer requirements.

- 24X7 support